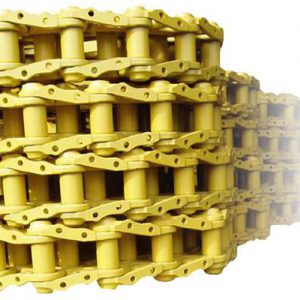

Steel (Track) chains for construction machinery

The steel chains in our range are made from high-quality materials. From the beginning, it was also our goal to shorten the production process and to balance the sales price of the chains at the lowest possible price level. In this way, we can offer you the highest quality of steel chains at fair prices.

Forged chain links

The chain links from our range are forged from high-quality boron steel. In the further process, they are cooled, tempered and induction-hardened using state-of-the-art machines. The result is high-strength chain links that shine with wear resistance and durability even under extreme working conditions.

|

|

Development of the chain links

The chain links that you receive from us are developed using the latest 3D CAD systems. The focus was on a maximum contact surface between the pins in engagement with the bushings.

The degree of hardness of the manufactured “rails” of the individual chain links is more than Rockwell C50, whereby the surface hardness in the optimum case goes up to twelve millimetres into the material depth. The core hardness is in the order of Rockwell C32. The latest wire cutting technologies (EDM) are used to profile the split links.

Sealed and lubricated steel chains for excavators

If you are looking for sealed and lubricated steel chains for your excavator, we have the right chains in our range. By means of synthetic high-pressure grease and modern polyurethane seals, optimal lubrication and a long service life are achieved.

Sealed and lubricated steel chains for bulldozers

We supply lubricated steel bulldozer chains which are sealed with high quality polyurethane seals and metal washers. This reduces the risk of dry joints with the focus on significantly increasing the service life of the steel chains.

Bushes and bolts

Support bushes and bolts have a significant influence on the quality and, in this context, the durability of the chain links. Geared to extreme loads, fit and sealing are optimised depending on the area of application and size. This ensures high durability and optimal usability in every area. With us you will find different types of support bushings and bolts for every conceivable area of application.

Wear resistance of the bushes

The bushings in our range are particularly wear-resistant and have a long service life. The Rockwell surface hardness of C55 is given here up to a maximum depth of 3.5 millimetres with regard to their outer contour. The surface of the inner bore has a Rockwell surface hardness of C53 up to a maximum depth of 3.5 millimetres.

Assembly of steel chains

The steel chains are assembled on fully automated production lines. The entire process, from inserting plugs and fitting seals to topping up oil, is fully computer-controlled. The individual pressure test of each individual connection minimises the risk of leaks. Assembly is carried out under strict inspection criteria, so that the risk of breakage during work is also reduced to a minimum.

Individual steel (Track) chains made to measure

You can also get custom-made, pre-assembled steel chains from us on request. The diversity of our range also offers you a wide range of floor plates.